London-based tech company Satori launched its first resin 3D printer, the compact yet professional ST1 600, in October of 2020, and innovated a partnership program at the same time in order to collaborate with global innovatives and inventors in the design and manufacturing industry to solve problems employ 3D reproducing. Now the female-led Satori, which signifies “enlightenment” in Japanese Zen, is getting ready to introduce its next resin system: the large-scale, industrial Satori VL2 800. Unlike its first printer, this one was developed through a strategic partnership with Chinese 3D etching company Elegoo, and will initially be sold through a Kickstarter campaign, which will begin sometime near the end of this month. This will help move the VL2800 more affordable, which isn’t often envisioned with sizable resin systems.

I recently had the chance to speak with CEO Chengxi Wang about the company’s newest addition, and she was able to give me a lot of information about it.

Let’s get right to the basics of the new VL2800: with a 278 x 156 x 300 mm develop capacity, the disguised stereolithography( MSLA) printer is large enough to print an part motorcycle helmet in one get, but pact enough to fit on your table. In fact, the “VL” in its word stands for volume, and Satori may potentially launch a printer with an even bigger volume in the future to join this new VL line. The resin printer features a 6K mono screen, which offers much faster cure durations than traditional screens and, according to Satori,” a 51 micron pixel immensity the whole surface of the erect platform .”

” For a resin printer, it’s very tough to balance magnitude and precision. That’s because when the screen is limited to a certain resolution, and you increase the volume of the machine, it’s almost like when you take a picture with a camera that doesn’t have enhanced resolution. When you zoom in, it is increasingly becoming pixelated, so the overall book excellence will be more blurry. But, what we did is we ameliorated the screen. In the previous machine, we applied 4K LCD screen, but for this version we consumed a 6K LCD screen, and overall that will retain our accuracy ,” Wang said.

She went to explain the importance of maintaining stability when you increase a printer’s capacity. A creator can increase the Z axis easily enough, but if it isn’t stable enough, you won’t end up with good prints.

” The great challenge for engraving large-scale capacity is that when you haul up the publish, it will create a very strong force that will suck this resin book down on the structure programme ,” she told me.

So you really need a stable Z axis when you’re dealing with a larger volume printer like this. For the new VL2800, Satori used a “KK module” from Taiwanese supply company HIWIN that better controls the stability use a closed loop-the-loop stepper motor and ball shafted, ensuring more consistent layer altitude and print skin-deep quality. Additionally, the printer also includes a self-monitoring feature for the Z axis machine, as in the past it would stop when it was encountered any difficulty.

” But with this feature, if the motor relates the problem, it won’t stop automatically–it will stop only after it finishes one layer, which allows us to have a consistent layer throughout the print and outcomes in a higher quality finish ,” she continued , noting that you really shouldn’t see layer texts with resin prints.

Again, Satori is using a mono screen for the VL2800, which helps increase etch raced by increasing the curing time of each layer.

” With a resin printer, a mono screen is more advanced than a hue screen, because it allows more light-colored to probe, which assistants the efficiency of the medicine process ,” Wang explained.

This 6K mono screen should make it possible to engrave constituents in sizes up to 27.8 x 15.6 x 30 cm, which is helpful for the types of employments that Satori is targeting with its brand-new plan. Some parties might not want a larger printer if they’re not publishing larger personas, but as Wang explained to me, the added benefit of the VL2800 is that” it makes it possible to do batch creation .”

” This is quite important for a company who wants to produce spare parts in work, like buckles or some other engineering spare parts ,” she said.

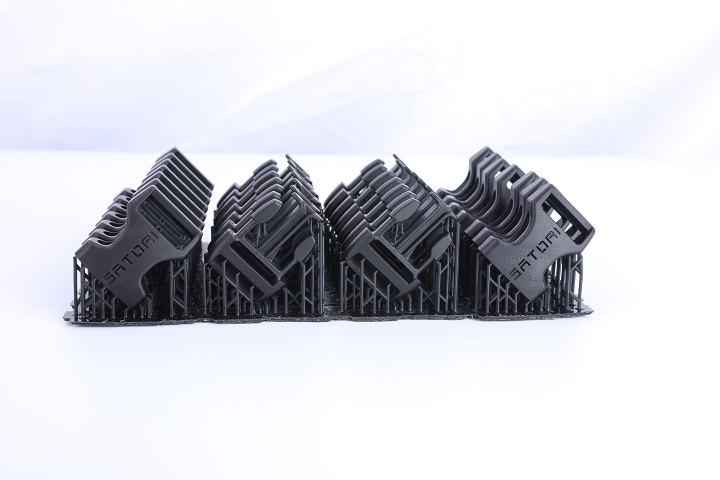

Satori researched its 3D printer’s mettle by 3D printing 50 fastens in about 3 hour, constructing it only four minutes of engraving per buckle.

” It will help people use the 3D printer for efficient customized production ,” Wang stated.

Wang explained that her insight for the brand-new VL2800 actually came from Satori’s partnerships with industrial designer Mahdi Naim.

” When we were developing the machine, we really wanted to use feedback from our design spouses and our community to help us must be considered what’s important ,” she clarified.” A pile of the manufacturing sector decisions can deviate from what a patron needs, just to push the tech specs higher and better, but for us it’s more what “the consumers ” needs .”

Satori and Naim recently collaborated once again to 3D etch a medical-grade prosthetic leg on its new method. Wang said that the results were” beyond our promises .”

” The larger an objective, the longer it takes to create and configure appropriate tools in order to make it by traditional means ,” Naim said during Satori’s newsletter.” With 3D publication, there are virtually no setup steps, so great prototypes are much faster to etch than moving them any other way. During our first collaboration on the WFH collection, I noticed that the Satori printer was precise and fast, the resin reveals the contour thanks to its relation to the light while opening a soft touch and stability .”

Naim is always working to push social impact in Africa, and by 3D reproducing prosthetics, they are more easily available to public areas that may not otherwise be able to open them.

Speaking of collaborations, Satori partnered with proved hobbyist-level 3D etching busines Elegoo to propel its latest fee printer, in order to help make it more accessible. Founded in 2015, Elegoo launched its Mars 3D printer–benchmarked against a PS1, 000 Zortrax system–for merely PS200 in 2019, and as Wang introduced it, the Mars lopes better, with better quality, and” hobbyists are crazy for this machine .”

Wang first noticed Elegoo during her brief stint as the CEO of MyMiniFactory.com, and kept in touch after she struck out on her own to start Satori. She says that even though Elegoo focuses on hobbyist printers, while Satori is aimed more at the professional level, she and the company’s CEO have a similar vision.

” I think it will be a good synergy when we join hands in this new launch ,” she said.

Satori, which to come to a brand-new role near the Tower Bridge in London at the end of April, also recently constructed a brand-new manufacturing middle near Elegoo in Shenzhen.

” We hired brand-new designers to supervise the quality control on site, so it’s a unusually reorganized process there ,” Wang clarified.” Our chief engineer is on site, and we’re hiring neighbourhood, and our brand-new part there will be finished in one month, are responsible for ensuring that the level of quality matches what we do here .”

In terms of what prepares its new printer apart from the rest of the herd, Wang mentioned the Way 3L resin printer, which rates about PS9, 000, which she said is” really quite a high price tag for designers who have this basic larger-volume need .”

” So for me, I understand there’s a magnitude need, but on the other hand, can we reduce the cost? So our machine is a combination of affordability and also the volume ,” she explained.

” The intellect we didn’t proceed even bigger is because we wanted to ensure the best combining of quality and stability in publication, and we believe this combining is the best we can do still further with this affordable price tag .”

Something else that shapes Satori’s VL2800 printer different from other resin organizations is its colour scheme. The company’s firstly printer, the ST1600, had a red and pitch-black designing aesthetic to competitor the company’s labelling, but this one is black and white. This idea came about when Wang was mustering feedback for this new printer, and noticed a social media affix of favorite resin printer brands for dental works, which included the ST1 600.

” I been acknowledged that our machine actually lost its identity among the crowd of all the dental 3D printers. Quite frequently, the resin 3D printer has either a crimson or orange cover-up, and to match that cover, it’s either black or grey as the cornerstone. There’s a ground for this–red and orange can block the UV light-colored fairly efficiently, but I requested our engineering team if it was possible to choose a different color, and I got notified that black color likewise manipulates ,” she explained.

” Black actually opens up the whole design flexibility, because as 3D printers became more prevalent in designer’s workspaces, extremely “when youre a secretary” from home, you don’t want a exceedingly inconsistent dye appearing in your pattern studio, you want it to be a neutral coloring .”

The design and color scheme for the brand-new printer was also inspired by the black and white scheme of her oven, and Samurai helmets, particularly in its include and how the door opens.

Wang said that Satori has validated the development of the VL2800 with paradigm structures, and, thanks to the support of Elegoo’s efficient manufacturing capacity, is ready to produce, meaning that the estimated delivery time will be much shorter than your average Kickstarter project, which is pretty exciting.

The campaign is set to launch later this month, but anyone interesting in regular Kickstarter informs and the chance to get exclusive early bird pricing for Satori’s brand-new VL2800 should sign up for the company’s newsletter mailing list. Too, remain adjusted to 3DPrint. com, because I’ll be sharing more exclusive message from Wang about the Kickstarter campaign soon!

The post Satori Set to Launch Kickstarter Campaign for New Industrial Resin 3D Printer performed first on 3DPrint. com | The Voice of 3D Printing/ Additive Manufacturing.

Read more: 3dprint.com

Recent Comments